Driving productivity

Delivering operational efficiency

- Process efficiency implementing innovation allows for more efficient use of equipment, capital and labour

- Competitive advantage introducing eloclearTM to your hygiene routine delivers a range of quantifiable benefits and savings

- Robust operation our scalable systems can be deployed in a range of settings, from factories and manufacturing facilities, to office spaces and warehouses

“Hygiene is the fastest growing area of cost. It is the first process to look at in order to produce safe food and drive sustainability. eloclear is transformational to the food industry.”

Food Industry Expert

In the food industry, we are prioritising food contact applications to help our customers reduce risk, improve hygiene outcomes and enhance microbial control. Food manufacturers can benefit from one solution that cleans and disinfects, reduces the reliance on hot water and simplifies the traditional cleaning and hygiene process.

Controlling cost in the hygiene process

There are a number of challenges presented by hot water cleaning methods, including:

- Energy costs to heat the water up to 70°C and consequently to re-chill the environment after cleaning

- Condensation from the heat increasing risk of microbial contamination

- Large volumes of water required and a high level of wastewater produced

- Hazardous chemicals used within the cleaning process, posing dangers to employees and the environment

- Resultant wastewater processing costs to remove the contaminants

As retailer standards increase and expectations grow for businesses to adopt more sustainable processes, the food industry is under immense pressure.

Hygiene is an area that offers an opportunity to reduce resource consumption whilst improving standards, and Ozo has the solution.

Introducing processes that use less water, heat and hazardous chemicals, whilst delivering full microbial efficacy offers commercial and environmental advantages.

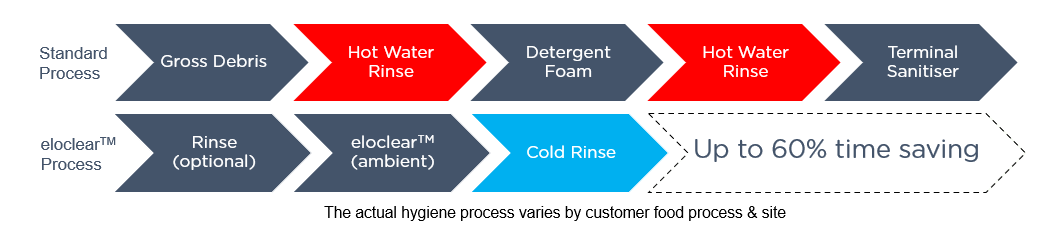

eloclearTM can streamline the traditional cleaning process by combining the cleaning and disinfection steps. It operates at an ambient temperature and requires just a single rinse step. Cleaning with eloclear™ reduces the amount of water, energy and time consumed, whilst combined cleaning and disinfection significantly reduces chemical usage. In turn, wastewater and associated processing costs are reduced, and businesses can benefit from increased operational capacity due to reduced cleaning time.

Comparing the traditional five-stage night time cleaning process in a food manufacturing setting, to Ozo’s two-step process using eloclear™: